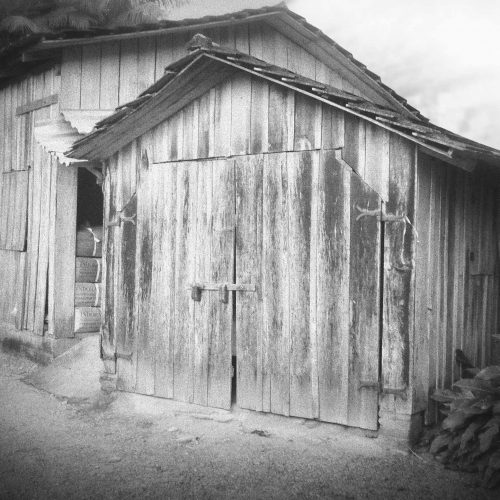

This is Zanotti Indústria e Comércio Ltda., a company with over 40 years of existence, with many stories to tell, great moments to share, and numerous new plans and goals to conquer. In 1981, Valdemar Zanotti combined his studies at the Chemical and Textile Industry Technology Center with his professional experience to found Transmar, a small company based in a 15m² shed that, at the time, had only six braiding machines for the production of elastic tapes.

Drawing the market's attention, growing and evolving, the company now known as Zanotti Indústria e Comércio Ltda. gained more and more customers, always at a fast pace, both in terms of technological advancements and delivery times for the customer. And so, Valdemar overcame each difficulty faced, creating jobs and forming a team he calls his "big family." With hard work and dedication, Valdemar Zanotti wrote a history of revolution in the Brazilian elastic tape market.

Zanotti in

numbers

Over 40 years in the market

Over 100,000 m² of built area

11 million meters of elastic tape produced per day

45,000 L of treated water. Production with environmental awareness

1,500 trained and engaged employees

Over 6,000 active customers

Over 20 countries served

#1 in elastic tapes in the Americas

Zanotti is a reference in the elastic tape segment throughout the Americas and one of the largest in the world. In Brazil, it operates across the entire country, in addition to marketing its products in almost all countries of the Americas and maintaining active contact on all five continents. Its products serve the entire textile chain and are present in people's daily lives in various forms: whether in the elastic tape of underwear or lingerie, hidden in clothes, in hospital products, footwear, automotive, and many other forms.

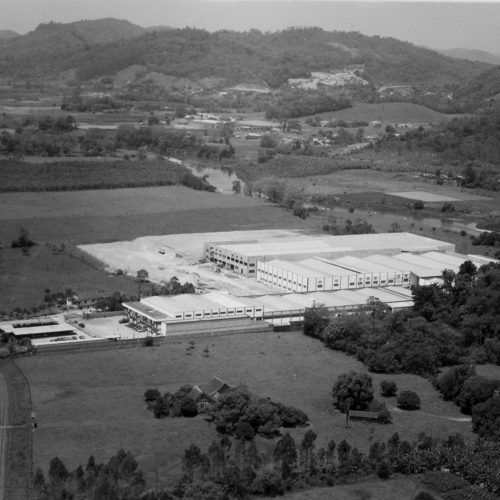

Today, the company produces over 11 million meters of elastic tape per day at its advanced manufacturing plant in Jaraguá do Sul, Santa Catarina, covering more than 100,000 square meters.

There are about 1,500 highly trained employees dedicated to producing with excellence and ensuring that the product reaches customers under the strictest quality standards.

This entire structure enables Zanotti to offer tailor-made solutions for the fashion industry. To achieve this result, Zanotti constantly invests in technology and market research — everything to ensure that customers receive their products with quality, competitive pricing, and fast delivery.

Our

History

How it all started?

The history of Zanotti began when Mr. Valdemar Zanotti took a course in Rio de Janeiro-RJ. Inspired, he returned to Jaraguá do Sul-SC with an idea and the desire to make it a reality.

In a small 15m² shed, located behind his parents’ house, the company was born, initially named Transmar. With just six braiding machines, Mr. Valdemar started the production of common elastic tapes at the time.

It was with simplicity, dedication, and a pioneering spirit that he laid the foundation for what would become a reference company in the elastic sector.

Purchase of Automated Machines

In 1992, with continuous growth and the acquisition of new customers, the company caught the market’s attention and changed its name to Zanotti S.A.

That same year, Zanotti took an important step toward modernization by acquiring automated machines, which boosted efficiency and production capacity. From that point on, the company had around 1,000 machines.

Construction of a Warehouse for Stock

In 1993, Zanotti took an important step to improve its efficiency by building an exclusive warehouse for stock. Before that, the process was slower, as raw materials were only ordered after the customer placed an order, resulting in an average delivery time of 60 days.

With the new warehouse, it was possible to create a strategic stock of raw materials, significantly reducing the delivery time to 30 days. This change marked a milestone in service agility and quality, reinforcing Zanotti’s commitment to customer satisfaction.

Crochet Machines Acquired

In 1995, Zanotti expanded its production with the acquisition of Crochet machines, diversifying its product line and no longer producing only the covered elastic tapes.

The following year, the manual dyeing process began, allowing the addition of color to the tapes.

Jacquard Machines Implemented

In 1997, Zanotti acquired Jacquard machines, expanding its product mix.

With this technology, it became possible to produce custom elastic tapes with writings and designs, meeting specific customer demands and allowing for greater product personalization.

Implementation of Automated Dyeing

In 2001, automated dyeing was implemented, marking a significant advancement in production. Before, the process was manual and did not guarantee color fidelity. The machines, imported from Germany, were specially adapted for dyeing elastic tapes.

Zanotti also stood out by becoming the only company in Latin America to have the Lawer Kitchen for dyeing, reinforcing its leadership and innovation in the market.

Pacatuba-CE Unit

In 2010, Zanotti expanded its operations with the opening of a unit in Pacatuba, Ceará, strengthening access to its products in the North and Northeast regions of Brazil. This unit allowed for faster deliveries in these areas, serving customers more efficiently.

At the Pacatuba plant, covered elastics and Jacquard tapes made of polyester are produced.

Current Manufacturing Plant

Today, we are the largest manufacturer of elastic tapes in the Americas. Our manufacturing plant covers over 100,000 m² of built area, and we serve more than 6,000 active customers, consolidating our leadership in the industry and our commitment to quality and innovation.

We manufacture tapes for various segments of the textile industry, always with the support of a qualified team dedicated to delivering excellence and meeting our customers’ needs.

© 2026. All rights reserved